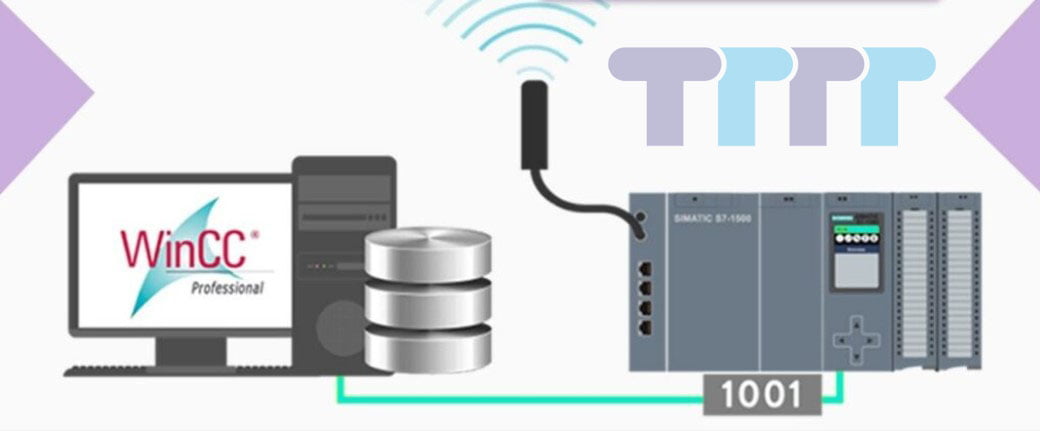

Currently, the use of remote control technologies applied to machines and equipment is no longer strange to factories, enterprises, industrial parks, etc. Therefore, operating a complex system and need remote monitoring is essential for a closed production line. The most used monitoring system today is the Scada system using PLC as a control and monitoring device on a computer.

You may be interested in the following articles:

- How to convert electricity into light energy is simple and vice versa.

- A fuse is a device used for what, its effect and structure.

Contents

What is scada remote monitoring system?

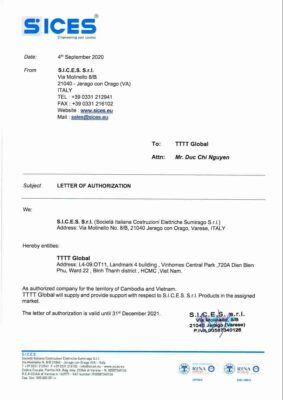

What is SCADA? The Scada remote monitoring system is a data acquisition and monitoring control system that supports us in the process of monitoring and remotely controlling a chain of hardware communication systems. The system is widely used on factories to monitor and control, change parameters for machinery and equipment.

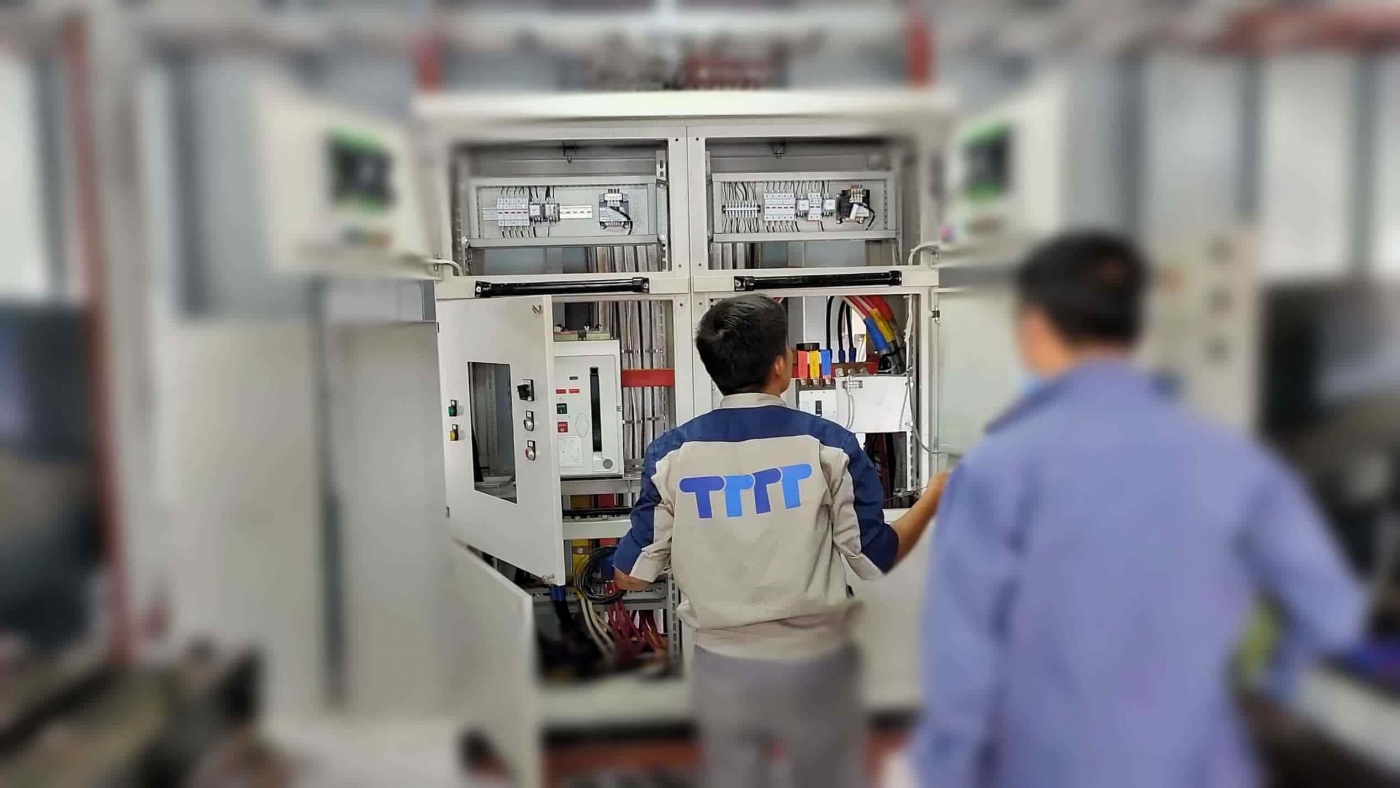

Scada TTTT has a lot of hardware and software components that aim to enable the following requirements to be fulfilled:

- Control and monitor the production process, industrial operation at local or remote places.

- Monitor, collect and process data in real time.

- Direct control with sensors, valves, machines, engines and other devices via human-machine interface.

- Record events in a diary.

Structure of the Scada system

The structure of the Scala system usually has 4 main parts including:

- The actuators: Including sensors, production lines, measuring devices, motors, machines are devices that take tasks from the system to execute the built-in tasks in the system. control system.

- Intermediate data acquisition station: RTU remote terminal units (devices that collect, analyze and process data between actuators and supervisory control systems) or control units PLC logic mistakenly ensures that the needs of the system comply with the set requirements.

- Communication system: Includes industrial communication networks, telecommunications equipment, and channel converters that transmit field-level data to control units and servers.

Remote generator monitoring control system: This system is responsible for monitoring the entire operation of the hardware and controlling the hardware system remotely.

See more: How important is the generator battery charger?

Applications and benefits of scada hmi

Apps of scada hmi

Scada has a wide range of applications, from small units to large factories and businesses with multiple plants. Monitoring systems are commonly used in automation applications allowing for efficient control and information collection that improves production costs and the efficiency of hardware systems.

The Scada hmi system is for all applications but different systems have different scada systems such as:

- Manufacture.

- Energy factory.

- Medicine.

- Wastewater treatment.

- Food & Beverage.

- Oil and gas industry.

- Recycling factory.

- Generator.

- And many other specific applications,…

Benefits of scada hmi

The scada hmi system with the above great features has brought a lot of benefits to the operation and management of the system such as:

- Improve efficiency: The entire system is usually automated, so it will ensure the production process and data information to increase production efficiency.

- Improve product quality: Through operations and data can come up with best practices to improve the product.

- Cost reduction: Because of the use of automation, labor costs and system maintenance costs are reduced.

See more: Summary of knowledge you need to know about generator controllers.

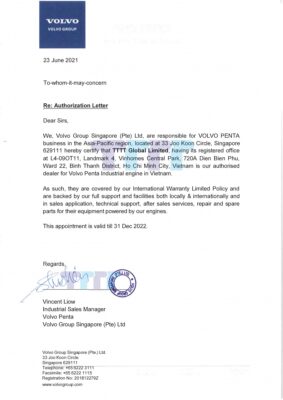

Company name:

TTTT GLOBAL co Ltd,.

Address: Landmark 4 Building, Vinhomes Central Park, 720A Dien Bien Phu Str, Ward 22, Binh Thanh District, Ho Chi Minh City, Vietnam.

Website: https://ttttglobal.com/en/

Hotline: +84286 2728 334

Email: Info@ttttglobal.com

CATEGORY: TECHNICAL QUESTIONS AND ANSWERS

RELATED POSTS

![[Warning] Cheap alternator, copy Mecc Alte on the market dau-phat-dien-cong-suat-lon-1](https://ttttglobal.com/wp-content/uploads/2022/04/dau-phat-dien-cong-suat-lon-1-533x400.jpg)