TTTT Global would like to show you Sices generator control panel manual TTTT. Detail of Sices generator controller manual, installation and manual user of ATS115/ DST4602/ GC315/ GC250/ GC400/ GC600/ MC200/ MC400 BTB200/ D-Monitor/ RN200/ HS315.

Contents

- 1 Sices generator controller manual, configuration

- 1.1 Sices generator controller configuration for system

- 1.2 Sices generator controller configuration for connection

- 1.3 Sices generator controller configuration for protection system

- 1.4 Sices generator controller configuration for other functional accessory

- 1.5 Sices generator controller configuration for connecting ports

- 1.6 Sices generator controller configuration for Canbus

- 1.7 Sices generator controller configuration for Plant

- 2 Set up Sices generator control panel diagram (GC315 Link)

- 3 Sices generator control panel diagram

- 4 Sices generator controller operating manual (GC 315 Link)

Sices generator controller manual, configuration

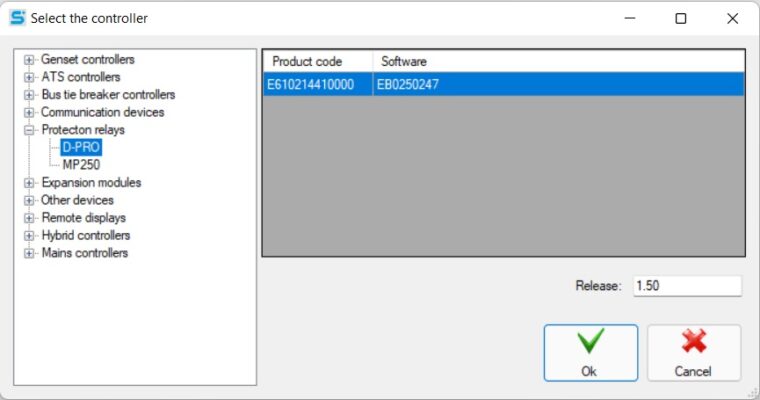

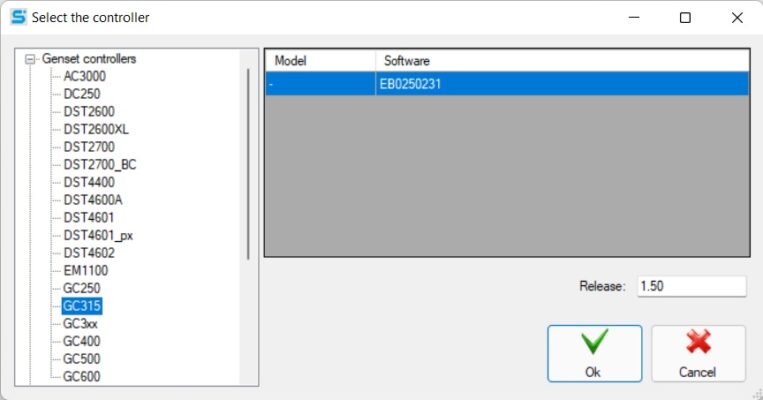

When using SICES controller in general and SICES GC315 Link in particular, we need to install BoardPrg4 software to set parameters for SICES GC315 Link. BoardPrg4 is software that supports the installation of SICES controller lines.

BoardPrg4 is available on TTTT GLOBAL homepage: SICES software download

After installing and starting the software, we choose to set parameters for SICES GC315 Link.

In the Sices generator control panel configuration, there are many parameters to be set, the main parameters include:

- System.

- Connection.

- Guard.

- Functional Accessory.

- Contact.

- Canbus.

- Installation.

Sices generator controller configuration for system

Engine

Fill in the motor power (kW).

Enter the rated speed when the frequency is 50Hz (rpm).

Enter the rated speed when the frequency is 60Hz (rpm).

Enter the number of flywheel teeth taken from the magnet.

Adjust the rpm/HZ ratio (rpm/Hz).

Generator

Select generator phase number (1 phase / 3 phase).

Enter the rated voltage of the generator (V).

Select whether the transmitter neutral is connected to the board (yes/ no).

Enter the rated power of the generator (kVA).

Select generator input voltage type (1-100V/ 0-400V).

Grid

Select the number of phases of the power network (1 phase / 3 phases).

Enter the rated voltage of the electrical network (V).

Enter the primary voltage of the transformer for the power network (V).

Enter the secondary voltage of the transformer for the power network (V).

Select whether the neutral of the electrical network is connected to the board (yes/ no).

Select the input voltage type of the power network (1-100V/ 0-400V).

Frequency

Enter the rated frequency (Hz).

Electric

Select system connection (on generator/on utility).

Enter the primary current of the system (A).

Enter the secondary current of the system (A).

Reference: Generator synchronization

Reference: Source protection device

Sices generator controller configuration for connection

Sensors on the grid

Enter the low grid frequency threshold (81<) (%).

Enter the threshold for high network frequency (81>) (%).

Fill in the low grid voltage threshold (27) (%).

Fill in the high network voltage threshold (59) (%).

Fill in the threshold for asymmetric variation of mains voltage (47) (%).

Fill in the time allowed grid presence delay(s).

Power time allows main fault delay(s).

Mains network options.

The engine begins to appear

Enter the threshold that allows the engine to start/stop the starter motor (rpm).

Enter the threshold that allows the engine to start/stop the starter motor (rpm).

Enter the threshold that allows the motor to start/stop the starter motor (V).

Enter the threshold that allows the motor to start/stop the starter motor (Hz).

Enter the threshold that allows the motor to start/stop the starter motor (D+).

Select allow slow disconnection of starter motor from oil pressure (yes/no).

Engine time

Enter the duration of the preheat cycle (s).

Enter the duration of the start command(s).

Enter the number of times the test starts.

Enter the time delay between two starts(s).

Enter the time of the stop order(s).

Enter the delay time before the “no stop” warning is triggered(s).

Enter the cooling cycle time(s).

Fill in the motor protection cover time(s).

Fill in the maximum time for the steady state condition(s).

Fill in the boot time before GCB closes(s).

Minimum temperature to allow dispensing (oC).

Fill cycle time at low speed(s).

Fill in the purge cycle time (gasoline only)(s).

Other parameters subdivide the sequence

Enter the time delay between opening the MCB and closing the GCB (and vice versa)(s).

Enter the minimum delay time between open/close orders (and vice versa) of the switch(s).

Select enable delivery due to not closing the MCB (yes/ no).

Select allow to accept test loads (yes/no).

Select to allow the MCB to be main powered (yes/no).

Select enable distribution enabled because GCB failed to open (yes/ no).

Choose to allow the MCB switch to be opened on (when ready/in case of power failure).

Sequence options.

Sices generator controller configuration for protection system

Generator protection

Frequency protection:

- Enter the minimum frequency threshold (81<<) (%).

- Enter the delay time for the minimum frequency (81<<)(s).

- Enter the low frequency threshold (81<) (%).

- Fill in the delay time for low frequency (81<)(s).

- Enter the high frequency threshold (81>) (%).

- Fill in the delay time for high frequency (81>)(s).

- Enter the maximum frequency threshold (81>>) (%).

- Enter the delay time for the maximum frequency (81>>)(s).

Voltage protection:

- Fill in the minimum voltage threshold (27<<) (%).

- Enter the delay time for the minimum voltage (27<<)(s).

- Fill low voltage threshold (27<) (%).

- Fill in time delay for low voltage (27<)(s).

- Fill high voltage threshold (59>) (%).

- Fill in the delay time for high voltage (59>)(s).

- Enter the maximum voltage threshold (59>>) (%).

- Enter the delay time for the maximum voltage (59>>)(s).

Current protection:

- Fill overcurrent threshold with time change (51) (%).

- Fill in the variable delay time for the current (51)(s).

- Fill in the fixed timeline overshoot threshold (50) (%).

- Fill in the overcurrent fixed delay time (50)(s).

- Select action for current protection (50/51).

Energy protection:

- Enter the energy inverse threshold (32R) (%).

- Fill in the energy inverse delay time (32R)(s).

- Enter the threshold for excitation loss (40) (%).

- Fill in the excitation loss delay time (40)(s).

Engine protection

Speed protection:

- Fill in the maximum speed threshold from the frequency (12) (%).

- Fill in the maximum delay time from ton number (12)(s).

- Enter the maximum closing speed threshold (12) (%).

- Enter the maximum closing delay time (12)(s).

Coolant protection:

- Enter the low refrigerant temperature threshold (oC).

- Fill in the low refrigerant temperature delay time(s).

- Enter the high refrigerant temperature threshold (oC).

- Fill in the high refrigerant temperature delay time(s).

- Enter the maximum refrigerant temperature threshold (oC).

- Enter the maximum refrigerant temperature delay time(s).

Oil protection:

- Fill in the low oil pressure threshold (Bar).

- Fill in the low oil pressure delay time(s).

- Enter the minimum oil pressure threshold (Bar).

- Fill in the minimum oil pressure delay time(s).

Fuel protection:

- Enter low fuel level threshold (%).

- Fill in the low fuel level delay time(s).

- Enter the minimum fuel level threshold (%).

- Enter the minimum fuel level delay time(s).

Battery protection:

- Fill in the time for the belt break delay(s).

- Select belt breaking action (pre-alarm/deactivate/alarm).

- Fill in the low battery voltage threshold (%).

- Fill in the low battery voltage delay time(s).

- Fill in the high battery voltage threshold (%).

- Fill in the high battery voltage delay time(s).

- Passenger protection measures for engines:

- Enter the delay time for the emergency stop button.

Sices generator controller configuration for other functional accessory

Planning

Working day:

- Choose a weekly schedule.

- Enter the starting time (time).

- Enter the ending time (time).

Auxiliary engine functions

DPF reconstruction:

Select DPF regeneration (Auto/force/force).

Historical Archives

Select the event to record.

Enter the analog fast recording interval.

Enter the analog slow recording interval.

Device

Date and time:

- Select daylight saving time (yes/ no/ auto).

- Enter the seasonal time difference.

- Enter the local time zone.

Display:

- Enter the time delay before the screen light turns off(s).

- Select options for screen backlighting (none/always).

- Single line diagram option.

- Keyboard screen options.

Alarm siren:

- Enter the siren’s offset time(s).

Sices generator controller configuration for connecting ports

Serial port 1

Select the connection port type.

Enter the Modbus address.

Select baud rate (Bps).

Select settings.

Select the order of Modbus registration.

Serial port 2 (GC250 not available)

Select the connection port type.

Enter the Modbus address.

Select baud rate (Bps).

Select settings.

Select the order of Modbus registration.

USB

Enter the USB address.

Select the order of the Modbus USB register.

Modem (GC250 and GC315 not available)

Select the modem type.

Select events to report.

Enter phone number 1.

Select a phone number type 1.

Enter phone number 2.

Select a phone number type 2.

Enter phone number 3.

Select phone number type 3.

Enter phone number 4.

Select a phone number type 4.

Select call mode.

Enter the number of rounds.

Enter the number of SMS.

Enter the number of data calls.

Ethernet (GC250 and GC315 not available)

Enter the IP address.

Fill in the subnet mask.

Enter the network port.

Enter Modbus/TCP port.

Fill in the web server port.

Fill in the NTP server port.

Enter the NTP server address.

Fill in the primary DNS server.

Fill in the secondary DNS server.

Enter the DHCP server port.

Fill in the DHCP server address.

Select the order of the Modbus Ethernet registers.

Select enable/disable SNMP.

Enter the SNMP manager’s address.

Fill in the SNMP message port.

SNMP notification event.

Si.Mo.Ne (GC250, GC315 and GC315 plus not available)

Choose to enable/disable incoming connections to Si.Mo.Ne.

Enter the IP address or hostname Si.Mo.Ne.

Enter the main server port Si.Mo.Ne.

Enter the IP address or the name of the Si.Mo.Ne sub host.

Fill in the Si.Mo.Ne sub server port.

Fill in the data sending time when the engine is running(s).

Fill in the data sending time when the motor is stopped(s).

Enter the time to send Keep Alive Network (min).

Select communication events.

Select the voltage type of the generator.

GPS (GC250, GC315 and GC315 plus not available)

Select enable/disable GPS module.

Fill in fixed GPS coordinates – Latitude.

Fill in fixed GPS coordinates – Longitude.

Fill in the motion sensitivity to send the event.

Enter the time to send data for tracking.

Mobile phone network (GC250, GC315 and GC315 plus not available)

Select mobile network mode.

Select LTE type.

Enter the primary APN (access point name).

Fill in the primary APN username.

Enter the password for the primary APN.

Secondary APN (access point name).

Fill in the secondary APN username.

Enter the password for the secondary APN.

Select the connection method.

Select Enable Modbus/TCP.

Select Modbus/TCP port.

Sices generator controller configuration for Canbus

Select the engine type.

Fill fine motor speed regulation (%).

Fill level control via Canbus.

Select mask to disable Canbus anomaly.

Select Droop/isochoronous for ECU.

Select to enable/disable Canbus fault signaling.

Enter the idle speed for the ECU (rpm).

Fill in the maximum time without notification from the engine(s).

Fill vertical line for up/down speed adjustment commands (%/s).

Enter the speed corresponding to the command 0% (rpm).

Enter the speed corresponding to the command 100% (rpm).

Select Opzioni per Canbus.

Enter ID to transmit on Canbus.

Sices generator controller configuration for Plant

Enter the name of the land.

Select the application type.

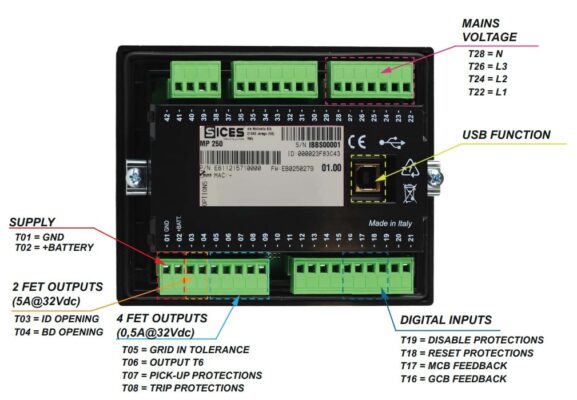

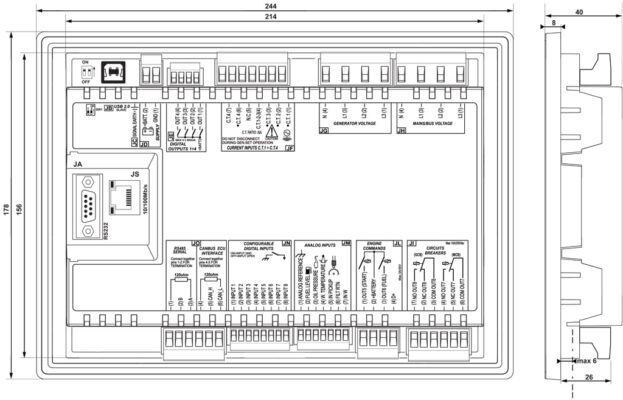

Set up Sices generator control panel diagram (GC315 Link)

JA: RS232 connection port.

JB: USB connection port.

JC: Expensive connector.

JD: Power supply:

- Pin 1: GND.

- Pin 2: Positive source.

JE: Pins 1-4: Digital output.

JF: Pins 1-7: Current input.

JG: Pins 1-4: Generator voltage.

JH: Pins 1-4: Power/bus voltage.

JI: Circuit Breaker:

- Pins 1-3: GCB.

- Pins 4-6: MCB.

JL: Pins 1-4: Motor command

JM: Pins 1-7: Analog input.

JN: Pins 1-8: Configurable digital inputs.

JO: Connect

- Pins 1-3: RS485 serial.

- Pins 4-6: CANBUS ECU interface.

JS: Ethernet connection port.

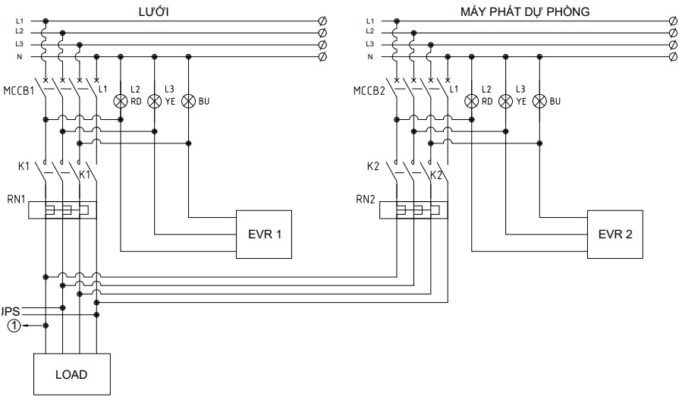

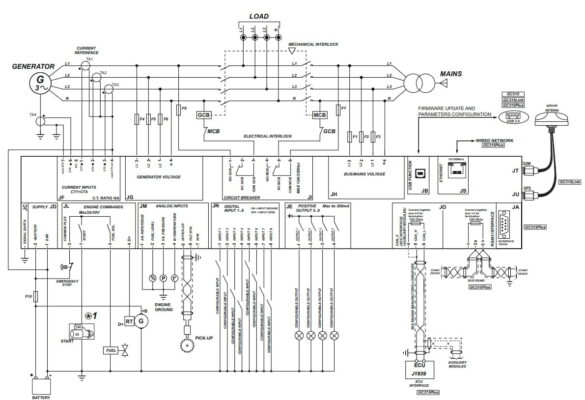

Sices generator control panel diagram

Sices generator controller operating manual (GC 315 Link)

After setting parameters and installing on the generator, the next thing is to operate the machine. Commissioning is the final step to put into use. The operating steps are as follows:

Check fuel.

Check engine coolant.

Check engine oil.

Evenly pump fuel to the engine.

Check the battery connector.

Manual start:

Step 1: Cut off the CB above the load.

Step 2: Turn on the controller power switch.

Step 3: Press select to manual mode.

Step 4: Press and hold the start button until the engine starts, then release.

Step 5: Use the up, down, left, right buttons to view system parameters.

Step 6: After the test is completed, turn on the CB to power the load.

Step 7: If you want to stop the machine, cut off the CB above the load.

Step 8: Press the stop button.

Auto start:

Step 1: Cut off the CB above the load.

Step 2: Turn on the controller power switch.

Step 3: Press select to auto mode.

Step 4: Check the parameters on the system.

Step 5: Turn on the CB supplying power to the load.

Note: If there is a GCB or MCB connection, you can use 2 buttons GCB and MCB on the screen to control the system shutdown.

If you need more information about generator control panel price, please contact us:

TTTT GLOBAL co Ltd,.

Address: Landmark 4 Building, Vinhomes Central Park, 720A Dien Bien Phu Str, Ward 22, Binh Thanh District, Ho Chi Minh City, Vietnam.

Website: https://ttttglobal.com/en/

Hotline: +84286 2728 334

Email: Info@ttttglobal.com

CATEGORY: SICES DOCUMENTS

RELATED POSTS

Tiếng Việt

Tiếng Việt