In modern standby and continuous power systems, the alternator plays a vital role in converting mechanical energy from the engine into stable and high-efficiency electrical power. Among the leading global manufacturers, the Mecc Alte alternator—engineered and manufactured in Italy—stands out with its comprehensive portfolio of generators designed to meet international standards such as IEC 60034-1 and ISO 8528, offering power ranges from a few kilovolt-amperes (kVA) to several thousand kVA.

Models such as the ECO, ECP, and C-Type series by Mecc Alte offer not only exceptional mechanical durability but also integrate advanced control technologies including digital AVR systems (DSR, DER), self-excitation capability, precise voltage regulation, and full support for parallel operations. These features meet the rigorous demands of heavy industrial environments, data centers, hospitals, and marine applications.

Contents

1.Technical Fundamentals of Mecc Alte Alternators

1.1 Basic Construction of an AC Alternator

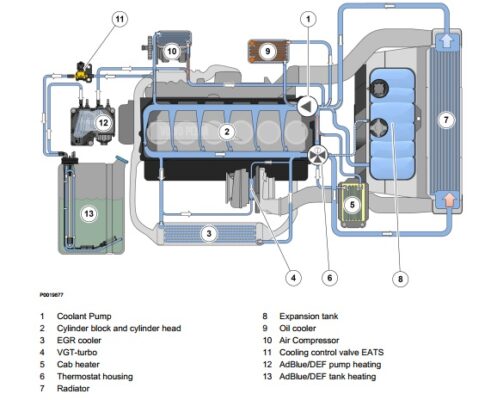

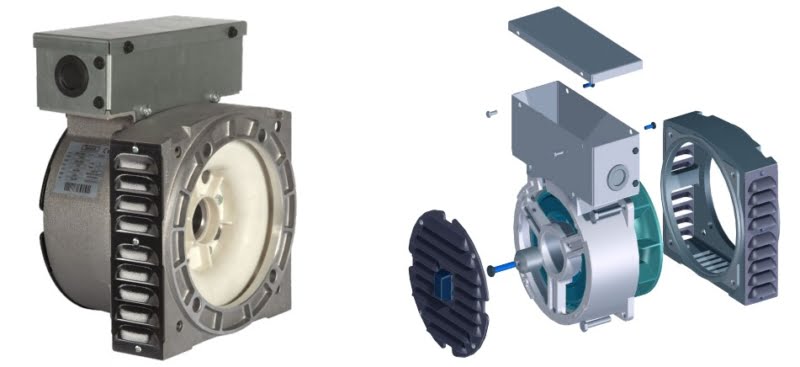

An Mecc Alte alternator is an electromechanical device that converts mechanical input (from an engine) into electrical output, primarily in the form of alternating current (AC). A standard AC alternator typically includes the following key components:

- Stator: The stationary part, consisting of wound copper coils. The stator generates voltage when exposed to a changing magnetic field.

- Rotor: The rotating component connected to the engine shaft. Depending on design, the rotor may use salient or non-salient poles and is equipped with excitation windings or permanent magnets to generate a rotating magnetic field.

- Rectifier: Typically a semiconductor-based bridge that converts AC from the exciter winding into DC to supply the rotor in self-excited systems.

- AVR (Automatic Voltage Regulator): Maintains stable output voltage regardless of load changes by adjusting excitation current.

- Bearings, Housing, Cooling Fan: Ensure mechanical stability, reduce vibration, and provide cooling under high-load conditions.

High-performance alternators such as those from Mecc Alte are engineered in compliance with international standards (IEC 60034-1, NEMA MG1), and use Class H or F insulation materials to maximize durability and thermal endurance.

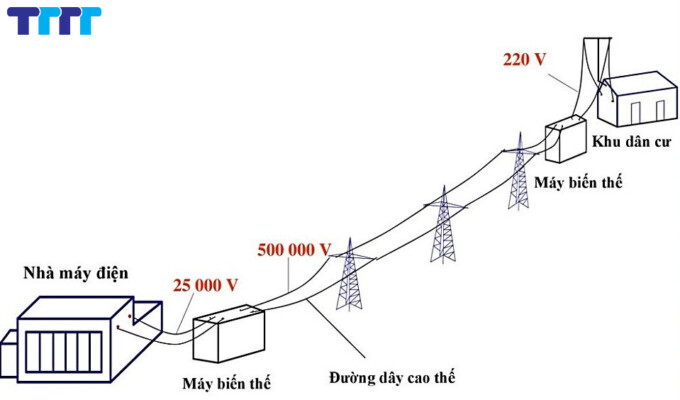

1.2 Electromagnetic Principle of Operation

Alternators operate based on Faraday’s law of electromagnetic induction. A rotating magnetic field produced by the rotor induces an electromotive force (EMF) in the stator windings. Several key variables influence the output voltage:

- Rotational Speed (RPM): Higher RPM results in higher voltage and frequency.

- Number of Poles (P): Affects frequency based on the formula: f = P x N x 1/120, where:

- f = Frequency (Hz)

- P = Number of poles

- N = Rotational speed (RPM)

- Magnetic Field Strength: Determined by excitation current and rotor magnetic structure.

- Winding Configuration: Defines rated voltage (e.g., 400V 3-phase, 220V single-phase), power factor, and harmonic distortion (THD).

For use in diesel or gasoline generator sets, the alternator must ensure easy startup, rapid load response, and stable performance under extreme environmental conditions (temperature, humidity, dust, etc.).

2. Technical Analysis of Mecc Alte Alternators

2.1 Mecc Alte Product Lines and Key Technical Specifications

Mecc Alte is a leading Italian manufacturer of alternators, offering a broad range from 1 kVA to 5000 kVA for residential, generator industrial, marine, telecommunications, and renewable energy applications.

Notable Series Include:

2.1.1 ECO and ECP Series – Most Common in Southeast Asia

- Power range: 7.5 kVA to 1000 kVA

- Pole configurations: 2, 4, 6-pole

- Compatible with major diesel engines: Perkins, Volvo, Cummins, Doosan, FPT, MTU

- Overload capability: up to 300% of rated current for 10 seconds (in select models)

- Total Harmonic Distortion (THD): < 4%, suitable for sensitive electronic equipment

2.1.2 C-Type Series – Optimized for Heavy Industrial Loads

- Power range: 500 kVA to 3000 kVA

- Class H insulation system

- Cooling options: air or oil

- Designed for continuous (prime) or standby duty

- Full support for paralleling and load sharing

Mecc Alte also produces brushless excitation systems that minimize mechanical wear, reduce maintenance needs, and enhance overall operational efficiency.

See more: Why are Italia alternator becoming increasingly popular in Vietnam?

See more: How Does Mecc Alte Generator Power Work? Answers For Beginners

2.2 Voltage Regulation and Integrated Protection Technologies

2.2.1 Automatic Voltage Regulators (AVR) – Intelligent Control Centers

Mecc Alte alternators incorporate advanced AVR models including DSR, DER, DVG, and UVR6, offering the following features:

- Automatic voltage regulation with ±1% accuracy

- Integrated sensors for temperature, current, and voltage

- Overvoltage, overcurrent, and excitation loss protection

- CANbus / Modbus interface for remote monitoring

- PC or mobile configuration support

The DSR is the most widely used AVR, supporting 3-phase sensing and closed-loop excitation control. The DER is optimized for high-power applications and load-sharing across multiple alternators.

2.2.2 Built-in Protection Features – Reliability and Safety

Mecc Alte alternators are engineered with robust protection mechanisms:

- Overvoltage Protection: Excitation shutdown when voltage exceeds thresholds

- Undervoltage Protection: Decreased excitation or fault signaling

- Overload Protection: Alarm and excitation current adjustment

- Short-Circuit Tolerance: Some models can withstand >300% rated current for 3–5 seconds

For parallel systems, Mecc Alte supports Droop CT and Digital Load Sharing, enabling automatic load distribution and frequency synchronization—critical for power plants, hospitals, and microgrid architectures.

| Topic | Technical Summary |

| Introduction to Mecc Alte Alternators | Mecc Alte offers high-performance alternators designed to meet IEC and ISO standards, covering a power range from a few kVA to several thousand kVA. |

| Alternator Function | Converts mechanical energy into AC electricity with stable output and high efficiency. |

| Key Components | Includes stator, rotor, rectifier, AVR, bearings, housing, and cooling system. |

| Electromagnetic Principle | Based on Faraday’s Law: rotating magnetic field induces voltage in stator coils; influenced by RPM, pole count, excitation current. |

| Winding & Voltage Configuration | Defines output voltage, power factor, and harmonic distortion (THD). |

| ECO & ECP Series | Power range: 7.5–1000 kVA; low THD (<4%); supports overload up to 300% for 10 seconds. |

| C-Type Series | Power range: 500–3000 kVA; Class H insulation; ideal for heavy-duty/continuous operation. |

| Brushless Excitation | Reduces mechanical wear and maintenance; improves reliability. |

Company name:

TTTT GLOBAL co Ltd,.

- Address: Landmark 4 Building, Vinhomes Central Park, 720A Dien Bien Phu Str, Ward 22, Binh Thanh District, Ho Chi Minh City, Vietnam.

- Website: https://ttttglobal.com/en/

- Hotline: +84286 2728 334

- Email: Info@ttttglobal.com