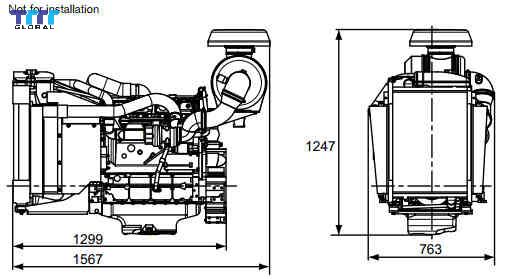

TAD530GE – Volvo Penta generator engine is one of the most popular industrial generator lines today, with a capacity of 131kW and stable operation. To help users have an overview of investment and operating costs, the following article will analyze in detail the costs associated with owning this engine.

Contents

Initial investment cost for Volvo Penta TAD530GE engine

When considering investing in an industrial generator engine, the initial cost is always the top concern. For the Volvo Penta TAD530GE engine, this is a significant investment but brings commensurate value in the long term.

Cost of purchasing the engine and accompanying equipment

The price of a brand new Volvo Penta TAD530GE engine ranges from 250-300 million VND, depending on the supplier and time of purchase. This figure may be higher than other generators of the same capacity on the market, but is considered worthy thanks to its superior quality and durability.

In addition, users need to calculate the cost of accompanying equipment such as controllers, control panels, sensors and cooling systems. These accessories usually account for about 15-20% of the engine value, equivalent to 40-60 million VND.

Installation and transportation costs

Installing an industrial generator engine requires high expertise and specialized equipment. Installation costs usually range from 20-30 million VND, including:

- Specialized technical workers

- Lifting and positioning equipment

- Wiring and conduit systems

- Initial inspection and calibration

Transportation costs depend on distance and terrain conditions, averaging from 5-15 million VND.

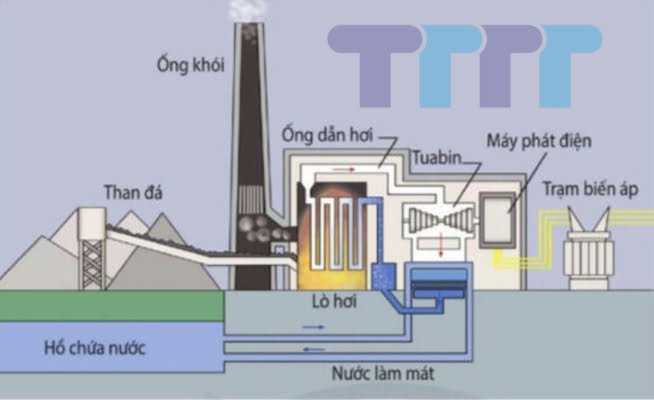

Generator room construction costs

A standard generator room needs to meet the requirements of space, ventilation and soundproofing. Construction costs are usually around 50-80 million VND, including:

The design and construction of the generator room must comply with strict technical standards on area, height, ventilation and noise protection systems. This is an important investment that directly affects the operating efficiency and life of the engine.

You may be interested in the following articles:

- What products and services does Volvo Penta store provide?

- Outstanding features and prices of Volvo Penta generators

Periodic operation and maintenance costs

To ensure stable and durable engine operation, periodic operation and maintenance must be strictly carried out according to the manufacturer’s recommendations. This cost is divided into many different categories.

Fuel and lubricant costs

The Volvo Penta TAD530GE engine has a fairly optimal fuel consumption compared to engines in the same segment. At 75% load, the engine consumes about 22-25 liters/hour. With the current diesel price, the average fuel cost per hour of operation is about 500,000 VND.

Regarding lubricants, the engine needs to be periodically changed every 250-300 hours of operation. Each oil change costs about 2-3 million VND, including labor.

Periodic maintenance costs

The maintenance schedule of the Volvo Penta TAD530GE engine is divided into many levels, from daily inspection to major maintenance. The average cost for each periodic maintenance ranges from 5-15 million VND, depending on the operating hours and machine condition.

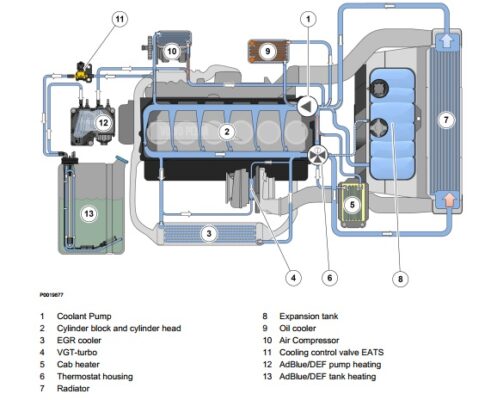

Regular maintenance items include changing the oil filter, fuel filter, checking and cleaning the cooling system, and checking operating parameters. These tasks should be performed by a team of specialized technicians.

Replacement parts cost

With high quality, Volvo Penta TAD530GE spare parts are quite expensive compared to the market. However, their durability and reliability help reduce the frequency of replacement, thereby saving costs in the long term.

Regularly replaced spare parts such as filters, belts, and water pumps cost from 2-10 million VND each time, depending on the component. For large parts such as turbos and high-pressure pumps, the cost can be up to tens of millions of VND.

Incurred costs and saving solutions

In addition to basic costs, users need to consider additional costs and find optimal solutions to save long-term operating costs for the Volvo Penta TAD530GE engine.

Insurance and certification costs

To ensure safety and compliance with regulations, generator engines need to be insured and periodically inspected. Annual insurance costs usually account for about 1-2% of the machine’s value, while safety inspection and certification costs range from 5-10 million VND per year.

This is a necessary investment to help protect users from technical and legal risks that may arise during operation.

Operator training costs

Operating the Volvo Penta TAD530GE engine requires specialized knowledge and skills. Initial and periodic training costs for operators can be up to 15-20 million VND per year.

However, this is an investment that brings clear results, helping to optimize machine performance and minimize the risk of damage due to improper operation.

Long-term cost-saving solutions

To optimize operating costs, users can apply many solutions such as detailed maintenance planning, monitoring operating parameters to detect problems early, and investing in modern monitoring equipment.

Using maintenance management and performance monitoring software also helps to optimize operating costs, although it may be expensive initially, it will bring significant savings in the long term.

Company name:

TTTT GLOBAL co Ltd,.

- Address: Landmark 4 Building, Vinhomes Central Park, 720A Dien Bien Phu Str, Ward 22, Binh Thanh District, Ho Chi Minh City, Vietnam.

- Website: https://ttttglobal.com/en/

- Hotline: +84286 2728 334

- Email: Info@ttttglobal.com