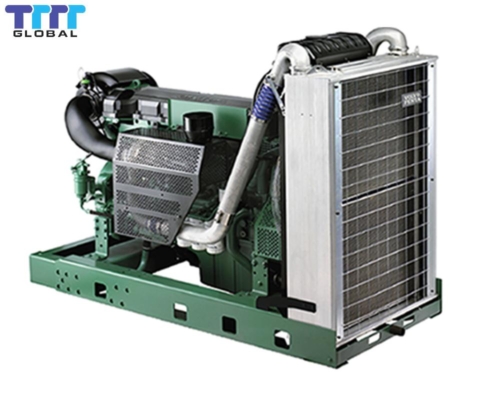

In today’s world where uninterrupted electricity is essential for industry and infrastructure, investing in reliable backup systems is crucial. The 300kva alternator, converting mechanical energy into three-phase AC power, has become a widely adopted choice among medium and large-scale enterprises. It offers a balanced performance-to-cost ratio, ideal for users who demand stability, efficiency, and resilience.

This in-depth article will explore the technical structure, key features, real-life applications, and maintenance considerations to help you leverage a 300 kVA alternator effectively.

Contents

- 1 1. Why Choose a 300kVA Alternator?

- 2 2. Construction and Operational Principles

- 3 3. Typical Technical Specifications

- 4 4. Sector-by-Sector Application Analysis

- 5 5. Advantages & Limitations of the 300kVA Alternator

- 6 6. Reputable Brands of 300 kVA Alternators

- 7 7. Common Technical Challenges & Remedies

- 8 8. Operating Costs & ROI Forecast

- 9 9. Purchasing Guidance & Best Practices

1. Why Choose a 300kVA Alternator?

The 300kVA alternator sits at a sweet spot in backup power—stronger than 200–250 kVA systems yet more compact and fuel-efficient than 400 kVA units.

Appropriate power capacity (~240 kW): Suitable for factories, hotels (4–5 stars), office buildings (5–10 floors), cold storage units, and mid-tier data centers.

Optimal fuel efficiency: Achieves its best SFC (specific fuel consumption) when operated at 60–80% load.

Manageable size: Easier to handle and install compared to bulkier 400–500 kVA alternators, but more powerful than smaller classes.

2. Construction and Operational Principles

Structural Components:

Stator: Converts rotating magnetic field into three-phase electrical output.

Rotor: Driven by diesel or gas engine at rated speed (usually 1,500 rpm for 50 Hz), generating rotating magnetic flux.

Automatic Voltage Regulator (AVR): Ensures output voltage remains stable under load fluctuations.

Bearings: Support rotor movement, minimizing friction and vibration.

Cooling System: Forced-air cooling (fans, ducts) to maintain safe internal temperatures.

Operating Principle:

When the rotor spins inside the stator windings, it induces a three-phase current. The AVR continuously regulates voltage to ±1%, adapting to load changes and maintaining waveform quality.

3. Typical Technical Specifications

| Specification | Standard Values |

|---|---|

| Rated output | 300 kVA (~240 kW) |

| Output voltage | 400 V – Three‑phase |

| Frequency | 50 Hz (60 Hz option for export markets) |

| Speed | 1,500 rpm (50 Hz systems) |

| Insulation Class | Class H (or Class F) |

| Power factor (cos ϕ) | 0.8 |

| Enclosure protection | IP23 to IP44 |

| Cooling mode | Forced-air ventilation |

4. Sector-by-Sector Application Analysis

Industrial Manufacturing

Ideal for powering CNC machinery, conveyor lines, presses, and packaging systems. Requires high stability for continuous operation over long shifts.

Commercial Buildings & Office Spaces

Supports HVAC systems, elevators, fire-safety systems, lighting, and surveillance. Voltage must stay within ±1% and waveform distortion (THD) needs to be minimal.

Cold Storage & Healthcare Facilities

Covers needs for medical equipment, refrigeration, laboratory devices, and vaccine storage systems. Demands extremely reliable, uninterrupted power delivery.

Construction Sites & Temporary Utilities

Used to run concrete mixers, water pumps, temporary site lighting, and mobile offices. Requires ruggedness, portability, and simple maintenance in outdoor conditions.

5. Advantages & Limitations of the 300kVA Alternator

Advantages:

Balanced capacity vs. cost: Optimal for mid‑size facilities with predictable loads.

Fuel‑efficient in its operating range: Best used at around 70% loading.

Widely available from reputable manufacturers: Easier to find spare parts and technicians.

Mechanical robustness and low vibration: Reliable operation under continuous use.

Limitations:

Higher upfront cost than smaller units: Compared with 200–250 kVA systems.

Technical maintenance required: Professionals needed for calibration, AVR setup, and alignment.

Not ideal for low‐load operation: Running below 30% for long durations can cause carbon build‑up and reduce lifespan.

6. Reputable Brands of 300 kVA Alternators

| Brand | Origin | Key Strengths |

|---|---|---|

| Mecc Alte | Italy | Compact design, high reliability, easy spare-parts |

| Stamford | UK | Excellent voltage regulation, global presence |

| Leroy Somer | France | Robust under harsh environmental conditions |

| Marathon | USA | Handles transient overloads and load spikes |

| Chinese OEMs | China | Budget-friendly, widely available parts |

7. Common Technical Challenges & Remedies

| Issue | Common Cause | Recommended Solution |

|---|---|---|

| Voltage instability | Faulty or inaccurate AVR | Upgrade to digital AVR; check wiring |

| Overheated windings | Poor ventilation, dust accumulation | Clean cooling systems; install thermal sensors |

| Rotor misalignment or vibration | Dirty/dry bearings or worn components | Redo bearing lubrication; rebalance rotor |

| Distorted waveform (high THD) | Unbalanced load or weak AVR | Use AVR with better voltage regulation; add filters |

| Burning smell or smoke | Overload, winding failure | Shut down machine, measure insulation resistance |

8. Operating Costs & ROI Forecast

Base cost for alternator only: ~ USD 3,500–5,000 or ~ 90–130 million VND

Complete power set (with engine, panel, canopy): ~ USD 15,000–18,000 or ~ 350–450 million VND

Annual maintenance cost: ~ USD 300–500 or ~ 8–12 million VND

Estimate lifespan: 15–20 years with proper upkeep

Best operating efficiency: When consistently loaded at 60–80%, ROI is most favorable

See also: Extend Lifespan Over 20000 Hours for 250kVA Alternator

9. Purchasing Guidance & Best Practices

Align specifications with your facility’s requirements: voltage, frequency, power factor, insulation, and enclosure rating.

Avoid oversizing: oversized alternators can lead to inefficient fuel use and reduced lifespan.

Choose a reputable supplier offering strong after-sales service and easy access to spare parts.

Combine condition monitoring and scheduled maintenance for optimal uptime: use CMMS, record logs, and consider real-time sensors.

Company name:

TTTT GLOBAL co Ltd,.

- Address: Landmark 4 Building, Vinhomes Central Park, 720A Dien Bien Phu Str, Ward 22, Binh Thanh District, Ho Chi Minh City, Vietnam.

- Website: https://ttttglobal.com/en/

- Hotline: +84286 2728 334

- Email: Info@ttttglobal.com