In today’s modern world, where electricity is the lifeblood of every industry, a 1000kVA alternator is no longer just a technical device – it is the backbone of stability, continuity, and safety across production and operational activities. Delivering up to 800 kW of real power, the 1000kVA alternator is often a strategic choice in backup or primary power systems for factories, data centers, airports, and critical infrastructure. However, to harness its full potential, one must have a deep understanding of its structure, technology, applications, and selection criteria.

Contents

Structure and Technology of the 1000kVA alternator

Mechanical Design and Magnetic System

At this power range, alternators typically use a rotating permanent magnet rotor and a three-phase stator with specialized winding techniques to maximize induction efficiency. Low-loss laminated steel cores, high-purity copper windings, and precision slot geometry help maintain voltage stability during continuous operation. Many models are modularly designed in three sections, facilitating transport and installation in tight spaces.

Excitation System and Voltage Regulation

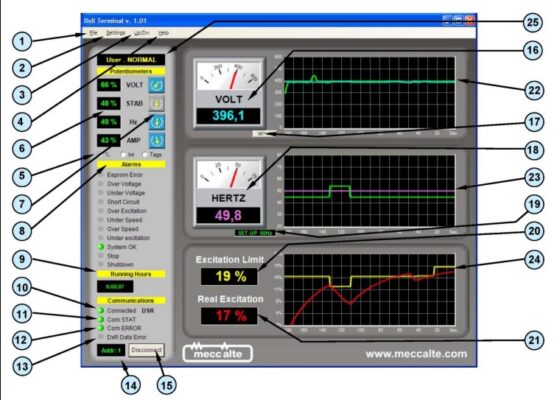

Brushless excitation systems are widely adopted to minimize maintenance. High-end alternators like those from Mecc Alte feature independent PMG (Permanent Magnet Generator) excitation systems, which offer superior voltage stability—critical for sensitive loads. Paired with intelligent AVR (Automatic Voltage Regulator) units, the system adjusts voltage in real-time to protect both the load and the alternator.

Applications in Specialized Industries

In data centers, hospitals, airports, and continuous-process manufacturing plants, a 1000kVA alternator serves as a highly reliable backup or even the main power source when grid stability is not guaranteed. With instantaneous load response and voltage accuracy within ±0.5% (Mecc Alte), it is a standard choice for paralleling systems or hybrid generator setups integrated with battery storage.

Key Selection Criteria for Alternators

Given the demanding operational environments, engineering teams must prioritize alternators certified to international standards such as IEC 60034, ISO 8528-3, and CE. Choosing between low-voltage (400V) and medium-voltage (6.6kV, 10.5kV) output significantly affects the total cost of electrical infrastructure. Alternators with IP23 or IP44 protection and Class H insulation are more durable in tropical or dusty industrial conditions.

The 1000kVA Alternator Mecc Alte

As one of the world’s leading alternator manufacturers, Mecc Alte of Italy has built a reputation for reliability, durability, and superior adaptability. Especially in the 1000kVA segment, Mecc Alte models not only meet international standards but are also optimized in volume and dimensions, making them easy to integrate into modern power systems.

Medium Voltage Design for Industrial Use

A key highlight is the availability of 10.5kV medium-voltage configurations – ideal for large factories or remote transmission setups. With windings designed to reduce energy loss, Mecc Alte’s medium-voltage alternators help ease the load on transformers, improve operational efficiency, and reduce overall capital expenditure.

Related: Italy Alternator Compact 33cm, Powerful 30kVA

Related: Premium Yacht Power Solutions with MeccAlte Alternator

Comparison Table: Mecc Alte vs Stamford vs Leroy Somer

| Technical Criteria | Mecc Alte (Italy) | Stamford (UK) | Leroy Somer (France) |

|---|---|---|---|

| Rated Power | 1025 kVA | 1000 kVA | 1000 kVA |

| Medium Voltage Options | Yes (6.6 – 10.5 kV) | Yes (up to 6.6 kV only) | Yes (model-dependent) |

| Excitation System | Independent PMG, brushless | Brushless with aux excitation | PMG / AREP |

| Insulation Class | Class H (standard) | Class H | Class F or H |

| Dimensions | Compact, container-ready | 10–15% larger | Average |

| Typical Applications | Heavy Industry, Marine, Military | Premium Residential | Premium Residential |

Advanced Technology and Ease of Maintenance

In addition to the PMG and advanced AVR systems, Mecc Alte integrates anti-corrosion materials, special insulation coatings, and vibration-resistant designs to prolong equipment life. These alternators operate reliably in humid, dusty, or mobile environments such as containerized generator sets. The three-module construction allows for easier transport, installation, and maintenance—saving both manpower and time.

Engine Pairing for the 1000kVA Alternator

Choosing the right engine to pair with a 1000kVA alternator is vital for system efficiency, fuel economy, and operational stability. Manufacturers typically match the alternator with 6–12 cylinder diesel engines, depending on actual power requirements.

Popular Engine Brands

1000kVA alternators are commonly paired with diesel engines from renowned brands such as Cummins, Perkins, MTU, and Caterpillar (CAT).

Synchronization Between Alternator and Engine

To ensure smooth operation, careful calculation is required for gear ratio (RPM), power factor, and output voltage. The standard generator speed is 1500 RPM (50Hz) or 1800 RPM (60Hz), and the engine must deliver around 880–950 kW of rated power to achieve 1000 kVA peak load. Cooling systems, vibration dampening, control panels, and mounting frames must be harmonized to reduce shock and extend system lifespan.

Company name:

TTTT GLOBAL co Ltd,.

- Address: Landmark 4 Building, Vinhomes Central Park, 720A Dien Bien Phu Str, Ward 22, Binh Thanh District, Ho Chi Minh City, Vietnam.

- Website: https://ttttglobal.com/en/

- Hotline: +84286 2728 334

- Email: Info@ttttglobal.com