Imagine a cement factory running at full capacity in the middle of the night. All grinding systems, rotary kilns, and conveyors are operating non-stop. But suddenly, the entire area experiences a blackout. Within just a few minutes, dozens of tons of raw materials risk being spoiled, machinery stops working, and thousands of workers are left waiting. Every minute that passes equals hundreds of millions of VND in losses.

This is not a distant scenario—it’s the reality that many Vietnamese businesses have experienced. And this is exactly why the 1300kVA alternator has become the top choice for factories operating around the clock—whether in food, textiles, cement, or electronics. With its powerful capacity, high durability, and instant response, this product is often described as an “energy shield” that ensures businesses can operate with peace of mind.

Contents

Why Do 24/7 Manufacturing Plants Need a 1300kVA Alternator?

Ensuring Uninterrupted Power in Any Situation

In modern industry, electricity is not just energy—it is the “lifeline” of the entire system. For factories that operate continuously 24/7, any power disruption leads to severe consequences.

A 1300kVA alternator is designed to provide a stable backup power source the moment the grid fails. Within just seconds, the entire production line is restored—no delivery delays, no equipment damage.

Meeting Large Power Demands for Industrial Operations

A typical manufacturing plant requires hundreds to thousands of kilowatts of electricity to operate. Equipment such as grinders, kilns, automated lines, and refrigeration systems consume enormous amounts of power.

The 1300kVA alternator delivers robust output sufficient to sustain an entire production line. This ensures that factories not only “survive” blackouts but also continue operating as if nothing happened.

Optimizing Long-Term Operating Costs

Many businesses worry that large-capacity generators will burn excessive fuel. However, modern 1300kVA alternators are optimized with advanced technologies:

Electronic Fuel Injection (EFI) system for efficient combustion.

Optimized combustion chamber design to reduce fuel consumption.

Eco-mode feature in certain models, lowering fuel use during partial loads.

As a result, businesses secure a reliable power source while saving on long-term fuel costs.

Real-World Applications of the 1300kVA Alternator

Cement Plants – Non-Stop Operation

The cement industry is a prime example of a sector that cannot afford downtime. When rotary kilns or clinker grinding systems are running, a sudden blackout can cause raw materials to clump and equipment to fail.

The 1300kVA alternator provides uninterrupted operation. Several major cement corporations in Vietnam have already installed this solution to safeguard production and ensure export schedules.

Food & Beverage Industry – Protecting the Cold Chain

In food processing plants, refrigeration and freezing systems are critical. Just a few hours of power loss can spoil hundreds of tons of materials, causing losses in the billions of VND.

The 1300kVA alternator ensures cooling systems remain stable, keeping products fresh and preventing shipment delays. This is why large dairy, meat, and seafood companies prioritize this investment.

👉 See also: Common Applications of the 2500kVA Alternator

👉 See also: 100kW Alternator for Agricultural Farms

Industrial Parks & High-Rise Buildings – Safety & Reliability

Beyond factories, many industrial parks, office complexes, and shopping malls also depend on the 1300kVA alternator because it:

Powers elevators, fire safety systems, and emergency lighting.

Maintains a professional image by preventing outages that affect clients and partners.

Complies with electrical safety regulations for large-scale projects.

See also: Applications of a 100kW Alternator in Modern Agriculture

See also: Popular application of 2500kva alternator

Comparison Table: Benefits of Using a 1300kVA Alternator

| Criteria | Value Delivered |

|---|---|

| Power Capacity | Supports entire production lines, 24/7 |

| Fuel Efficiency | EFI & eco-mode save 15–20% costs |

| Durability | Average lifespan 15–20 years with proper maintenance |

| Applications | Cement, textiles, food, industrial zones |

| Safety & Stability | Instant response when grid fails |

Key Tips for Choosing the Right 1300kVA Alternator

Prioritize Reputable Global Brands

The market is full of suppliers, but not all products meet standards. Businesses should select brands certified by DNV, ISO, CE, ensuring international quality.

European and Japanese brands are often preferred for their durability, easy-to-replace components, and reliable performance under harsh conditions.

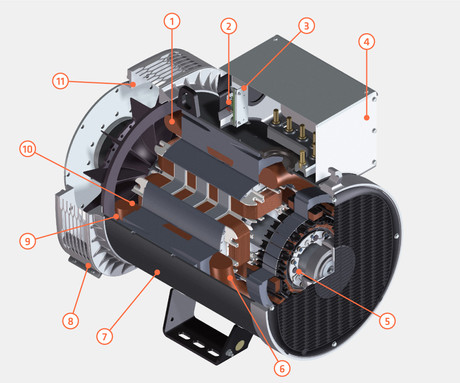

Pay Attention to Integrated Control Systems

A modern 1300kVA alternator isn’t just about raw power—it’s also about smart control:

Automatic start-up during blackouts.

SCADA compatibility for remote monitoring.

IoT integration in certain models, allowing technicians to check system status directly via smartphone.

After-Sales Service – The Decisive Factor

Some companies buy cheaper machines only to struggle with maintenance. A 1300kVA alternator truly proves its value when backed by reliable after-sales service:

Readily available spare parts.

24/7 on-call engineering support.

Scheduled maintenance to extend machine life.

This is what gives businesses the confidence to operate long-term without worrying about unexpected failures.

Company name:

TTTT GLOBAL co Ltd,.

- Address: Landmark 4 Building, Vinhomes Central Park, 720A Dien Bien Phu Str, Ward 22, Binh Thanh District, Ho Chi Minh City, Vietnam.

- Website: https://ttttglobal.com/en/

- Hotline: +84286 2728 334

- Email: Info@ttttglobal.com