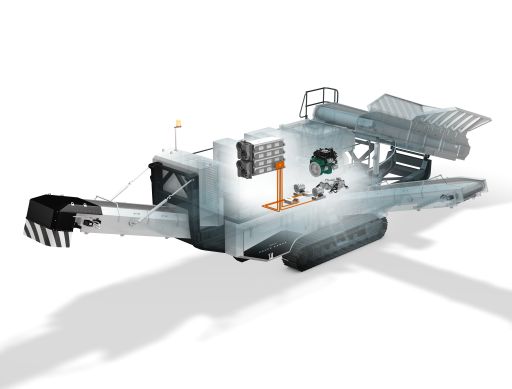

Volvo Penta off-road engine is the engine line with the largest market of Volvo Penta, the engine is researched and equipped with many technological achievements in the production process. In addition to reducing emissions, Volvo Penta engine can be used in a variety of applications to improve productivity, uptime and total cost of ownership. There are five engine lines – D5, D8, D11, D13 and D16 – offering power from 105-585 kW (143-796 hp). Below is an overview of Volvo Penta industrial engine products analyzed by TTTT, for your reference.

Click on the model to download and view engine specifications or contact your dealer VOLVO Vietnam for more information.

| Model | Power kW | Rpm | Litre |

| Volvo Penta TAD540VE | 105 | 2,200 | 5,1 |

| Volvo Penta TAD541VE | 129 | 2,200 | 5,1 |

| Volvo Penta TAD542VE | 160 | 2,200 | 5,1 |

| Volvo Penta TAD550VE | 105 | 2,500 | 5,1 |

| Volvo Penta TAD551VE | 129 | 2,300 | 5,1 |

| Volvo Penta TAD552VE | 160 | 2,300 | 5,1 |

| Volvo Penta TAD840VE | 160 | 2,200 | 7,7 |

| Volvo Penta TAD841VE | 185 | 2,200 | 7,7 |

| Volvo Penta TAD842VE | 210 | 2,200 | 7,7 |

| Volvo Penta TAD843VE | 235 | 2,200 | 7,7 |

| Volvo Penta TAD1140VE | 235 | 2,100 | 7,7 |

| Volvo Penta TAD1141VE | 265 | 2,100 | 10,8 |

| Volvo Penta TAD1142VE | 285 | 1,700 | 10,8 |

| Volvo Penta TAD1340VE | 256 | 2,100 | 12,8 |

| Volvo Penta TAD1341VE | 275 | 2,100 | 12,8 |

| Volvo Penta TAD1342VE | 210 | 2,100 | 12,8 |

| Volvo Penta TAD1343VE | 332 | 2,100 | 12,8 |

| Volvo Penta TAD1344VE | 352 | 2,100 | 12,8 |

| Volvo Penta TAD1345VE | 394 | 2,100 | 12,8 |

| Volvo Penta TAD1640VE | 405 | 1,900 | 16,1 |

| Volvo Penta TAD1641VE | 450 | 1,800 | 16,1 |

| Volvo Penta TAD1642VE | 515 | 1,900 | 16,1 |

| Volvo Penta TAD1643VE | 565 | 1,800 | 16,1 |

Advantages of Volvo Penta VE industrial engine

Model table of popular Volvo Penta Volvo Penta off-road engine

Depending on the needs and utilities that customers need, TTTT has compiled a series of commonly used Volvo Penta off-road engine models. These lines are used by professional equipment manufacturers around the world, please have a look:

Volvo Penta industrial engine with maximum uptime

VE Stage V engines with power over 560 kW must have a diesel particulate filter (DPF) to capture and store soot. The soot needs to be burned to regenerate the DPF and this is usually done while the machine is down, known as active regeneration. However, Volvo Penta off road engine TTTT industrial engines have a “Regeneration Zero” generation meaning they have minimized the need for active regeneration as much as possible, reducing downtime and keeping the Volvo Penta TTTT’s industrial engine. maximum performing customers for profit. Through an optimized engine and exhaust system that work seamlessly together, the Volvo Penta solution increases uptime by maximizing the use of passive regeneration. Here, the soot accumulated in the DPF is ignited during normal operation of the machinery, without the need for regular re-operation during shutdown.

Improved fuel efficiency

The Volvo Penta diesel engine offers up to 5% – 10% reduction in fuel consumption compared to other brand lines, contributing to an extremely attractive total cost of ownership. Lower fuel consumption also means less CO2 emissions into the atmosphere, helping to reduce greenhouse gases and enabling customers to meet their sustainability goals.

Simple installation

All Volvo Penta VE engine stage V are engineered to fit the model they replace, meaning customers don’t have to redesign their machines to accommodate the new engine. With Volvo Penta’s two-box after-treatment system, customers benefit from simple, flexible installation.

Many options optimized for your operation

Volvo Penta off-road diesel engines are specifically designed for applications in different segments and environments, such as forestry, agriculture, mining, material handling and construction projects. There are five base engines – D5, D8, D11, D13 and D16 – delivering power between 105-585 kW (143-796 hp). When combined with a variety of hardware options, the engine architecture can be specifically designed to meet the needs of many types of applications.

Easy Volvo Penta VE engine servicing and maintenance

To increase the reliability and uptime of the engine range, Volvo Penta has improved predictive serviceability and extended service intervals. For example, oil change service intervals have now been doubled from 500 to 1,000 hours.

Volvo Penta VE Applications

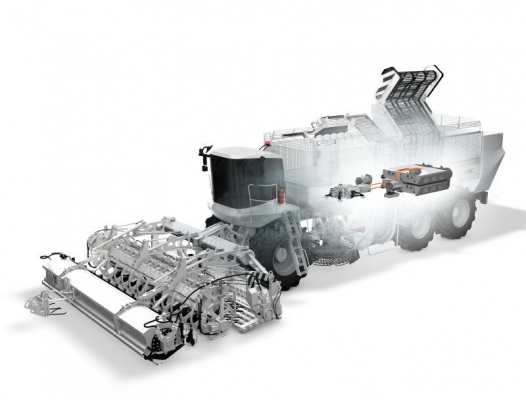

Volvo Penta VE engine for agricultural machines

Short and long-term harvest seasons demand reliable performance – a need that is fully met by our wide range of agricultural engines.

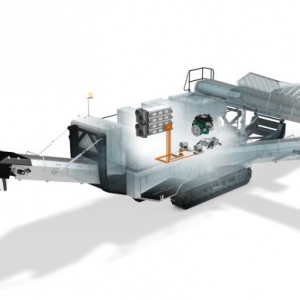

Volvo Penta for construction machines

In construction, where uptime and uninterrupted power are key, our industrial motors will protect your uptime.

Volvo Penta engine for forest mining machine

Rough terrain and remote environments don’t stop our Volvo Penta excavator engine either. They provide the powerful performance and reliability required.

Volvo Penta diesel engine in the material handling industry

From warehouses to docks, Volvo Penta’s powerful and easy-to-maintain engines power everything from tractors to forklifts to cranes.

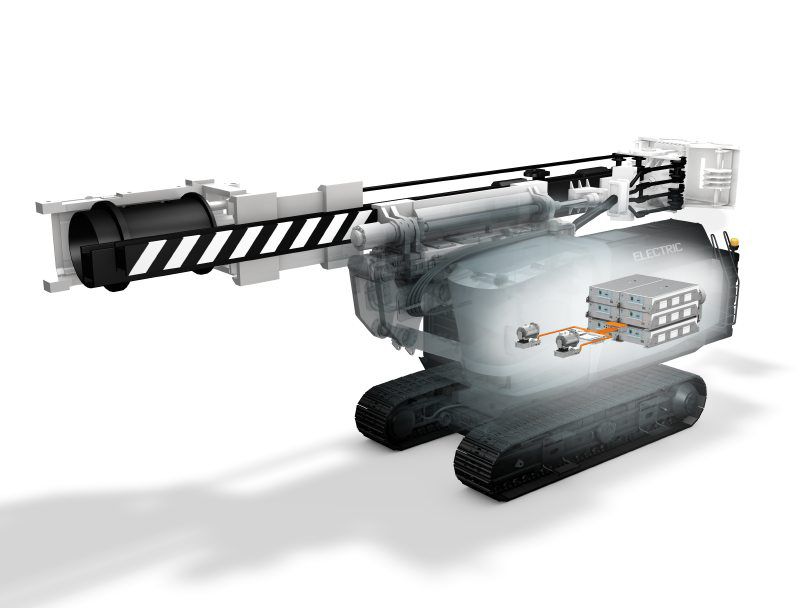

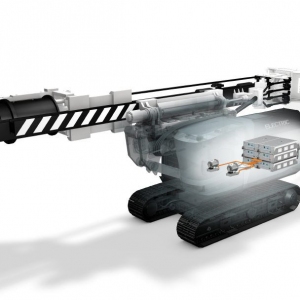

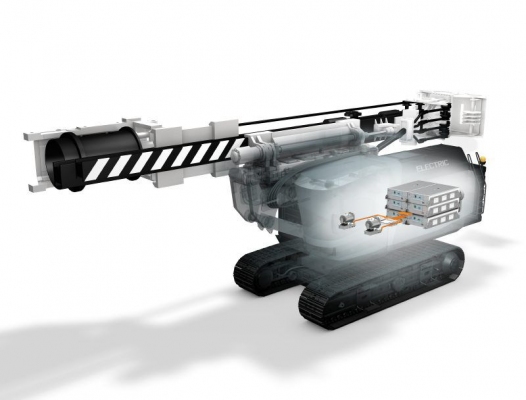

Volvo Penta industrial engine for mining machinery

For long hours underground, in really harsh conditions, our reliable heavy-duty engine makes the difference.

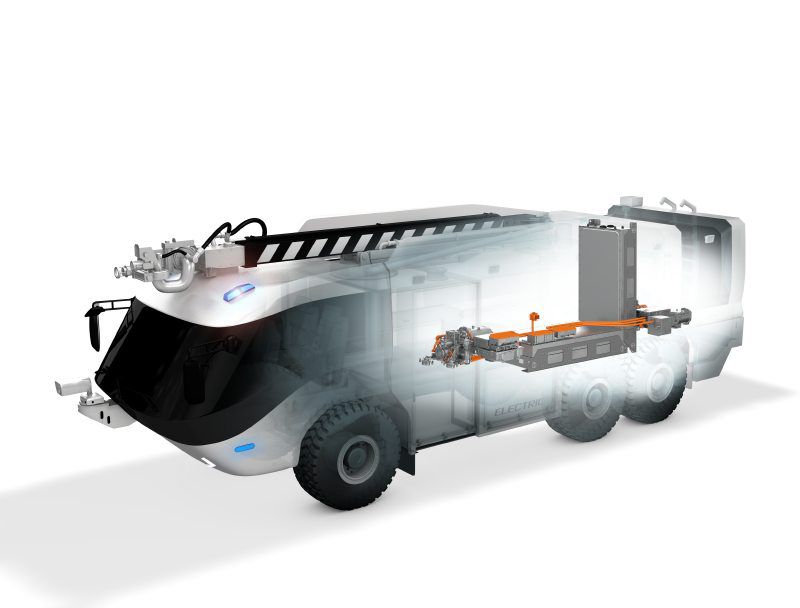

Volvo Penta industrial engine for special purpose vehicles

Off- or on-road. Airport fire truck or snow removal machine. Our oil pump motor is guaranteed to keep you running.

Contact for more information about Volvo Penta spare parts:

TTTT Global Co., Ltd.

Address: Landmark 4, Vinhomes Central Pank, 720A Dien Bien Phu, Ward 22, Binh Thanh District, City. Ho Chi Minh, Vietnam.

Website: https://ttttglobal.com/en/

Phone: 0286 2728334

Email: Info@ttttglobal.com

Tiếng Việt

Tiếng Việt